Hello, I am Fujimori, a MITUBACI craftsman.

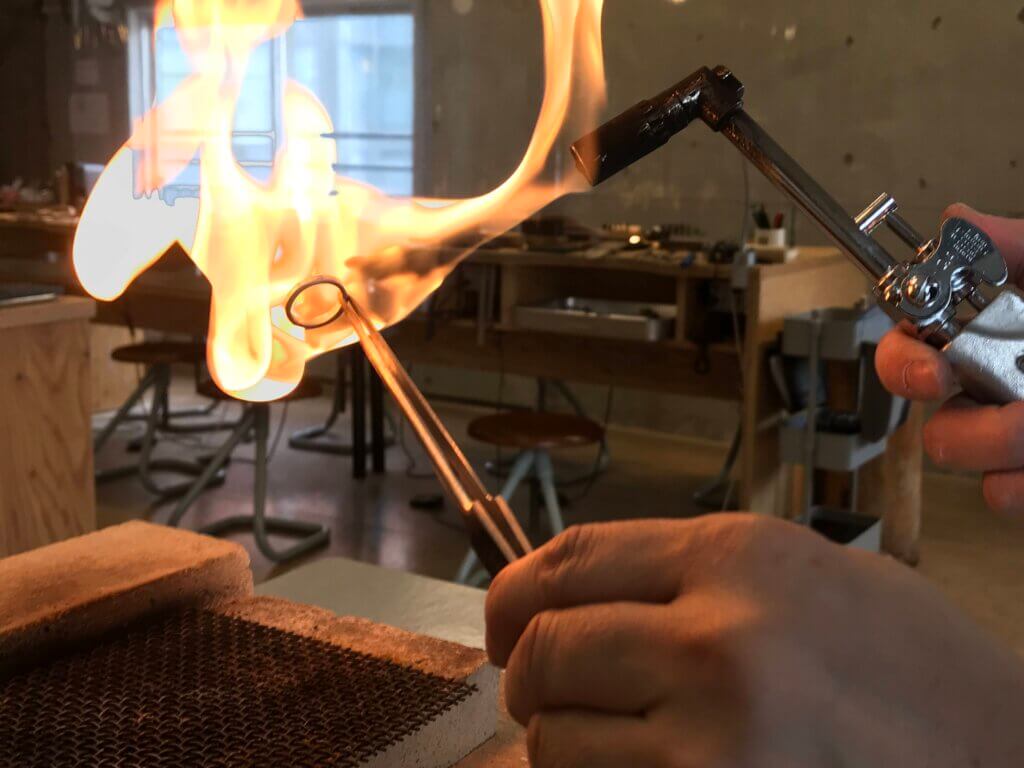

In this issue, we will introduce a workbench that uses fire for brazing, annealing, etc., and tools used for brazing.

Brazing is a technique for joining metals (gold, silver, etc.) by melting and pouring a metal (gold or silver solder or other soldering material) mixed to melt at a temperature lower than the melting point of the metal to be joined into the gap between the metals to be joined (gold, silver, etc.) using heat and allowing the material to solidify upon cooling.

Annealing is a technique in which heat is applied to metal to homogenize the structure and soften the metal, making it easier to handle when working.

Let us begin with the workbench where fire is used.

Bricks are laid on desks and tables to prevent them from burning when a fire is used. There are various types of bricks: bricks used for gardening, bricks for parking lots and sidewalks, and bricks used for pizza ovens and other types of furnaces. There are two types of bricks depending on how they are made: hot-rolled bricks, which are baked at high temperatures, and sun-dried bricks, which are dried in the sun and hardened. Because sun-dried bricks are vulnerable to rain, the bricks used in Japan are thermoformed bricks. Thermal bricks include ordinary bricks, fire-resistant bricks, and fire-insulated bricks (heat-resistant bricks), each of which has its own characteristics. Ordinary bricks are called red bricks and are resistant to water. They are mainly suited for gardening. While ordinary bricks are water-resistant, fire-resistant bricks and fire-insulating bricks are heat-resistant bricks. Refractory bricks have heat resistance and heat storage properties, and once heated, they do not easily cool down. They are mainly used inside kettles and fireplaces. Refractory insulating bricks are characterized by their heat resistance and heat insulation properties, and are used to surround refractory bricks on the outside of kettles and fireplaces. They are expected to keep kettles and fireplaces warm because of their heat-insulating properties, which prevent heat from escaping. Both refractory bricks and refractory insulating bricks can withstand heat up to 1,200°C to 1,300°C. MITUBACI uses refractory insulating bricks to prevent heat transfer underneath the bricks as they are used for metal brazing and annealing with a burner fire.

Thus, there is no danger of scorching the tabletop because the workbench is covered with fire-resistant insulating bricks to prevent heat.

In the case of a mixed air/gas burner, the temperature for annealing, silver, and gold soldering is about 700°C to 1,000°C. Therefore, a stainless steel mesh is placed over the fireproof insulating bricks. By placing a stainless steel mesh, a space is created between the brick and the base metal (silver, etc.), making it easier to raise the temperature of the base metal. When using an oxygen burner, a heat-resistant ceramic plate is placed on top of the fire-insulated bricks. When working with an oxygen burner, the temperature of the refractory insulating bricks rises above the refractory temperature of 1,300°C. Although it is possible to work on the refractory bricks, the refractory bricks may melt, so a heat-resistant ceramic plate is placed on top of the refractory bricks. Refractory ceramic plates with a refractory temperature between 1650°C and 1800°C should be used.

In this way, we create a work area where we can use a fire with a burner.

Next, we will introduce the necessary tools for brazing.

Blow burner and compressor

When air is fed through a compressor and mixed with gas, it reaches a high temperature of about 1300℃. It is mainly used for processing silver and gold.

Oxygen burner

It is used by mixing oxygen and gas from an oxygen cylinder. it can reach high temperatures of up to about 2000℃. Mainly used for platinum processing.

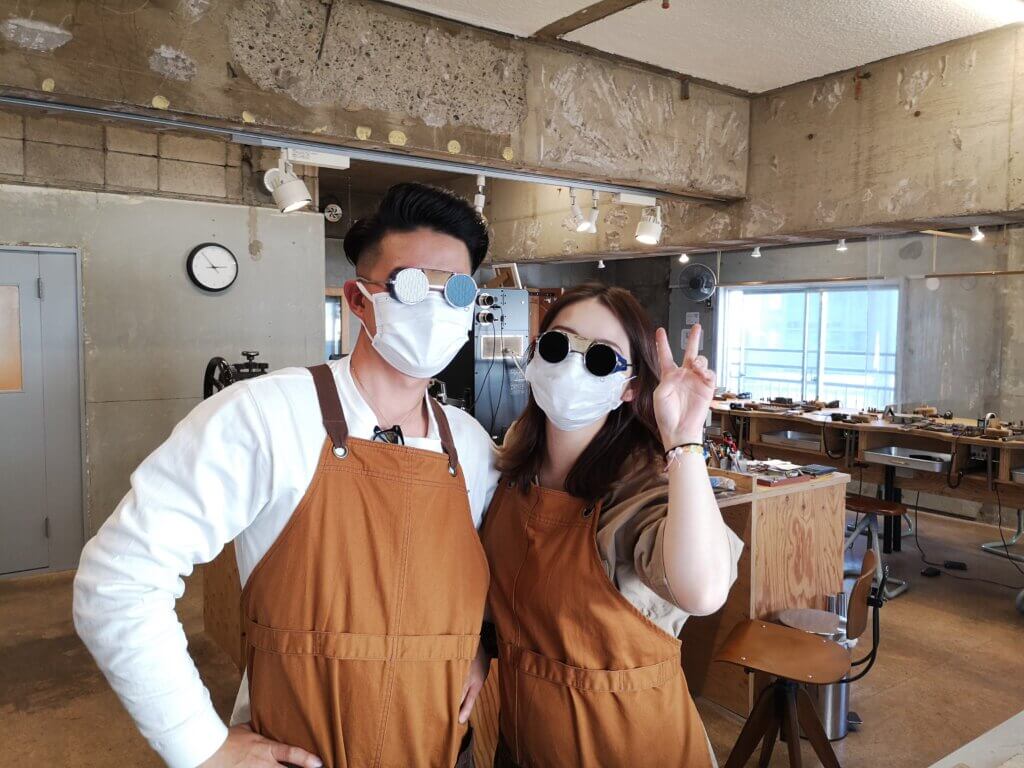

Protective Glasses

Used for eye protection during oxygen welding. Direct exposure to hot metal using an oxygen burner causes the eyes to flicker.

For more information about burners, please see our previous blog.

Tweezers

There are many different types of tweezers, so we will introduce three that are particularly necessary for use at MITUBACI. All are made of stainless steel.

The first is a pair of tweezers with a narrow, pointed tip and a length of about 12 cm to 13 cm. The first is a pair of tweezers with a thin, pointed tip, 12 cm to 13 cm long, which is very easy to use to pinch small objects, and is mainly used when placing solder material on top of rings during brazing. The second type of tweezers has a slightly rounded tip and is about 19 to 20 cm long. These tweezers are used to hold rings that have been heated by the fire during brazing or annealing. Since these tweezers are long, they are safe to grip hot rings.

The third is a pair of inverted tweezers about 19 to 20 cm long. These tweezers are used to hold the ring between the tweezers and hold it in place when brazing, and then braze the ring with a burner. The long tweezers allow you to hold the ring between the tweezers and braze it with the tweezers in your hand.

These three bottles are very useful.

Brazing ring stand

Used to stand rings when brazing.

It is efficient because several rings can be brazed side by side.

Tabletop igniter for LC burner

When the buttons on all four sides are pressed, a ticking sound is heard and a small amount of electricity is generated in the center of the burner. Press the tip of the burner while letting out a little gas, and the electricity will ignite the flame. It is a little tricky to use, but once you get used to it, it ignites quickly. Since the burner can be lit with one hand, it can be used quickly and efficiently, and is very convenient.

This time, I introduced only tools around the fire, but there were a lot of them. Engraving requires a lot of tools. In the workshop, please try to touch tools that you have never used before. And please enjoy the experience of jewelry making safely.