I am Fujimori, a craftsman at MITUBACI.

Today, we would like to introduce the electroplating equipment in MITUBACI's workshop.

What is plating?

Plating is a process of covering the surface of a material with a thin film of metal.

Plating adds color, resistance to discoloration, rust resistance, strength, and makes the substance more usable.

In the case of jewelry, plating is also often applied to the metal and is mainly used for decoration and to give it a better look. in the case of MITUBACI workshops, silver jewelry is created and then plated on request to give it a yellow gold color or pink gold color can be enjoyed.

Plating Mechanism

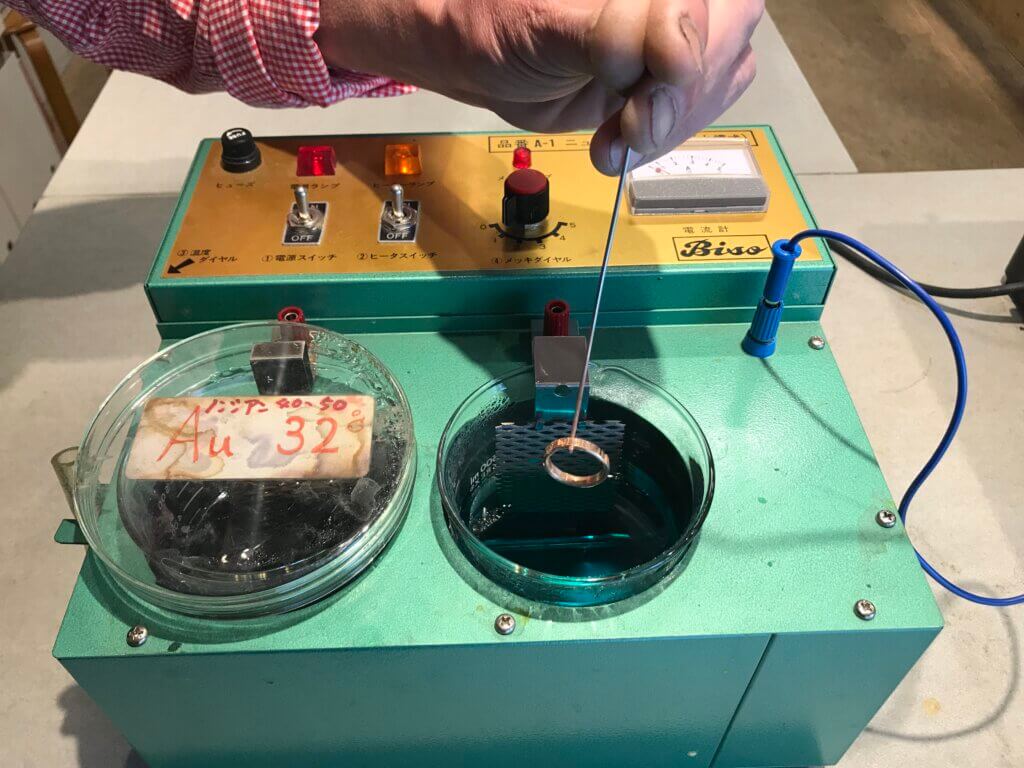

This is the plating equipment used at MITUBACI.

A machine that applies plating using electricity.

The mechanism of this plating system utilizes the "oxidation" and "reduction" properties of matter.

The round part of the machine is a beaker. You have used it in science experiments. The left side of this beaker contains the liquid for yellow gold plating, and the right side contains the liquid for pink gold plating. These liquids are aqueous solutions containing the metal ions of the respective color gold. When plating, the metal dissolved in the aqueous solution is electrolyzed as the anode (+ pole) and the metal to be plated (in this case, silver ring, silver bangle, etc.) as the cathode (- pole). Then, a reduction reaction occurs on the silver jewelry (cathode) side and combines with the metal that has separated from the liquid and come out. The combined metal becomes a thin film of metal that covers the surface of the ring or bangle. This process will cause the silver jewelry to be "plated" and become the color of yellow or pink gold.

Let's actually apply the plating.

The mechanics of plating equipment is difficult. It's like a science textbook.

The actual plating procedure is not that difficult, although it requires some knack. It can be used even if you do not know how it works.

1 Turn on the plating equipment and adjust the temperature of the plating solution.

Each plating solution has its own operating temperature.

2 Wash and degrease the product to be plated thoroughly in an ultrasonic cleaner.

Oil on the product may cause uneven plating.

3Put the product in the plating solution.

The yellow and pink gold will gradually darken in color as it is placed in the plating solution, and the yellow and pink gold will adhere to the product.

In the case of the machine and water solution used at MITUBACI, the plating is completed when it is placed in the plating solution for about 7 to 13 seconds.

MITUBACI can apply yellow gold plating or pink gold plating to silver rings, bangles, and pendants made at the Silver Workshop on the spot. You can take your jewelry home on the same day.

Won't the plating come off?

Unfortunately, the gold plating applied to silver jewelry gradually fades with use and falls off with further use.

When the plating is removed, the color of the base silver is revealed.

MITUBACI's workshops are designed toIf you wish, we can re-polish and re-plate them, so please feel free to contact us if you have any concerns.

A plating processing fee of 3,300 yen (tax included) will be charged again.